Business

Inside Rubber Extrusion: Crafting Precision Components for Industry

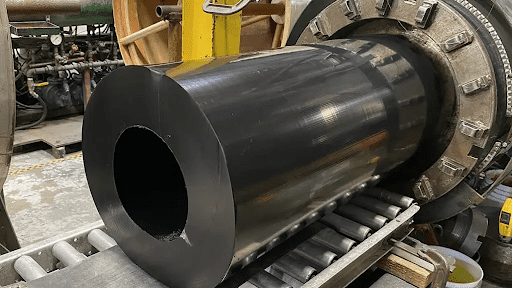

The production of durable seals, gaskets, and tubes essential for various industries relies on the intricate process of rubber extrusion. This method transforms raw materials like EPDM rubber and neoprene rubber into precision components used in sectors such as automotive, construction, and electronics. Understanding the steps involved offers insight into how manufacturers ensure high-quality results.

Understanding the Rubber Extrusion Process

Rubber extrusion involves pushing raw rubber through a specially designed die to create continuous profiles. This resembles squeezing toothpaste from a tube, where the paste takes on the shape of the nozzle. The choice of material is crucial; EPDM rubber is favored for its resistance to sunlight and weather, making it ideal for outdoor applications, while neoprene rubber is preferred for its ability to withstand oils and temperature fluctuations.

Before the extrusion process begins, manufacturers must prepare the rubber compound. This preparation includes mixing raw rubber with additives such as stabilizers, pigments, and curing agents. Each ingredient serves a distinct purpose. For instance, stabilizers enhance durability, pigments provide color, and curing agents ensure the rubber hardens appropriately during the vulcanization process. Stringent quality control measures guarantee that each batch meets defined standards, as even minor variations can impact the final product.

The Key Stages of Extrusion

The extrusion process is the core of manufacturing. The prepared rubber compound enters a heated barrel where it is softened. A rotating screw within the machine pushes the rubber through the die, determining the product’s final shape—whether a circular tube, flat strip, or custom seal. Temperature regulation is critical during this phase; excessive heat can burn the rubber, while insufficient heat can hinder its flow. Skilled technicians monitor the process closely to maintain consistency and precision.

After extrusion, the rubber is referred to as a “green” product, which is then cooled before undergoing vulcanization. This heating process creates cross-links between polymer chains, enhancing the rubber’s durability and elasticity. For instance, EPDM rubber seals are designed to remain flexible in extreme temperatures, while neoprene rubber tubing is engineered to withstand oil exposure and mechanical stress.

Once vulcanization is complete, manufacturers cut the continuous rubber into specific lengths based on customer specifications. Some products may require additional processing, such as adhesive application or surface coating. Quality control remains paramount, with inspections focused on dimensional accuracy, surface finish, and elasticity. Advanced measuring tools ensure that each product adheres to the highest standards, particularly in precision-driven sectors like automotive manufacturing.

The versatility of extruded rubber products extends across numerous industries. In the construction sector, EPDM rubber is commonly used for window and door seals due to its excellent weather resistance. Similarly, neoprene rubber finds applications in marine and industrial settings, where it is utilized for hoses, belts, and protective covers due to its resilience against oil and heat.

Manufacturers today are also focusing on sustainability. Initiatives aimed at reducing material waste and energy consumption are increasingly prioritized. The introduction of recycled rubber compounds in non-critical parts helps minimize environmental impact. Furthermore, automation and computer-controlled extrusion lines enhance accuracy and consistency, allowing manufacturers to produce high-quality rubber products efficiently while adhering to eco-friendly standards.

The journey from raw rubber to a perfectly shaped component exemplifies industrial precision. Skilled rubber extrusion manufacturers combine technology, expertise, and innovation to create reliable products that are essential to modern life. Whether producing EPDM rubber weather seals or neoprene rubber tubing, each item undergoes a meticulous process, highlighting the science and craftsmanship involved in shaping materials that support countless applications worldwide.

-

Entertainment2 months ago

Entertainment2 months agoIconic 90s TV Show House Hits Market for £1.1 Million

-

Lifestyle4 months ago

Lifestyle4 months agoMilk Bank Urges Mothers to Donate for Premature Babies’ Health

-

Sports3 months ago

Sports3 months agoAlessia Russo Signs Long-Term Deal with Arsenal Ahead of WSL Season

-

Lifestyle4 months ago

Lifestyle4 months agoShoppers Flock to Discounted Neck Pillow on Amazon for Travel Comfort

-

Politics4 months ago

Politics4 months agoMuseums Body Critiques EHRC Proposals on Gender Facilities

-

Business4 months ago

Business4 months agoTrump Visits Europe: Business, Politics, or Leisure?

-

Lifestyle4 months ago

Lifestyle4 months agoJapanese Teen Sorato Shimizu Breaks U18 100m Record in 10 Seconds

-

Politics4 months ago

Politics4 months agoCouple Shares Inspiring Love Story Defying Height Stereotypes

-

World4 months ago

World4 months agoAnglian Water Raises Concerns Over Proposed AI Data Centre

-

Sports4 months ago

Sports4 months agoBournemouth Dominates Everton with 3-0 Victory in Premier League Summer Series

-

World4 months ago

World4 months agoWreckage of Missing Russian Passenger Plane Discovered in Flames

-

Lifestyle4 months ago

Lifestyle4 months agoShoppers Rave About Roman’s £42 Midi Dress, Calling It ‘Elegant’